Depending on the business profile, meat plants are required to meet relevant standards and regulations regarding the conditions in which meat products are produced, processed and stored. The requirements vary, to all enterprises involved in the production of meat or the production of cured meat products (sausages, hams, pies and other animal products, e.g. fats) and enterprises engaged in the transport of the above-mentioned products.

Who are legal requirements for?

Legal requirements related to meat processing, transport and storage apply to all processing factories, involved in the supply chain related to meat production and processing. It mainly concerns:

- Butcher’s shop – enterprises dealing in the production of sausage products and animal products. The regulations also apply to butchers carrying out marginal, local and limited activities

- Slaughterhouses (slaughterhouses) – plants for slaughtering, eviscerating and dividing them into carcases

- Transport – transport companies dealing in the transport of meat and products resulting from its processing

- Points of sale, restaurants (not described in this article) – facilities that are the end of the supply chain, covered by the requirements related to Good Hygienic Practice / HACCP. Requirements described in Regulation (EC) No 852/2004

Legal requirements

Requirements regarding rules related to hygiene in establishments related to meat processing and its transport, including monitoring of environmental conditions in the production and processing of meat products are specified in the following documents:

- Regulation (EC) No 853/2004 of the European Parliament and of the Council of 29 April 2004 laying down specific hygiene rules for food of animal origin

- Regulation (EC) No 852/2004 of the European Parliament and of the Council of 29 April 2004 on the hygiene of foodstuffs

In addition, the principles of Good Manufacturing Practice, Good Hygienic Practice and quality management system including hazard analysis and critical control points of HACCP should be implemented in production industry.

Temperature requirements

The key parameter monitored in meat processing factories is temperature. The temperature of the rooms in which the products are processed and stored as well as the temperature of the products themselves should be monitored. Temperatures are determined depending on the type of meat/meat products as follows:

- The meat of domestic ungulates (Regulation (EC) No 853/2004, Section I):

‘During cutting, boning, trimming, slicing, dicing, wrapping and packaging, the meat is maintained at not more than 3ºC for offal and 7ºC for other meat, by means of an ambient temperature of not more than 12ºC or an alternative system having an

equivalent effect;’‘In the absence of other specific provisions, meat after post-mortem inspection must be chilled immediately at the slaughterhouse to ensure a temperature of all parts of the meat not exceeding 3°C for offal and 7°C for other meat, with a cooling curve ensuring a constant temperature drop. However, meat may be boned and cut before it reaches the temperature (…)’

- The meat of poultry and lagomorphs (Regulation (EC) No 853/2004, Section II):

‘After inspection and evisceration, slaughtered animals must be cleaned and cooled to not more than 4°C as soon as possible, unless the meat is cut warm.’

‘During cutting, boning, portioning and cutting, wrapping or packaging, the meat temperature was not more than 4°C, by maintaining an ambient temperature not more than 12°C or by another alternative system having an equivalent effect’.

In the case of slaughtering on the holding:

‘Delayed eviscerated poultry obtained from a breeding farm may be kept for 15 days at a temperature not exceeding 4°C. It must then be eviscerated at the slaughterhouse or cutting plant located in the same Member State as the breeding farm concerned.’

- Wild game meat (Regulation (EC) No 853/2004, Section IV):

‘In a reasonable period of time after killing the animal, chilling should be allowed to reach a temperature of all meat not higher than 7°C. If the climate permits, it is not necessary to subject the animal to active cooling.’

- Minced meat, meat preparations and mechanically separated meat (MSM) (Regulation (EC) No 853/2004, Section V):

‘All meat working must be organized in a way that prevents or minimizes contamination. To this end, food business operators must ensure that:

(a) the meat temperature does not exceed 4°C for poultry, 3°C for offal and 7°C for other meat;

And

(b) the meat was brought into the workrooms progressively as needed;

(c) Immediately after preparation, minced meat and meat preparations must be packaged in wrapping or packaging and:

(…)

(i) chilled to an internal temperature of not more than 2°C for minced meat and 4°C for meat preparations;

Or

(ii) frozen to an internal temperature of not more than -18°C.’

- Storage and transport of MSM:

‘C) If MSM is not used immediately after receiving it, it must be placed in the unit or collective packaging, and then cooled to a temperature not exceeding 2°C, or frozen to an internal temperature not higher than -18°C. These temperature requirements apply during storage and transport.

d) If the IMO is not used within one hour of its receipt, it must be immediately cooled to a temperature not exceeding 2°C.

(e) If, within 24 hours after cooling, MSM is not processed, it must be frozen within 12 hours of manufacture and within six hours it must reach an interior temperature of not more than -18°C.

f) Frozen MSM must be placed in unit or collective packaging before storage or transport, it cannot be stored for more than three months, and during storage and transport the temperature should not be kept higher than -18°C. “

Requirements relating to temperature monitoring

The requirements related to the monitoring of environmental conditions in meat processing plants are described in Regulation (EC) No 852/2004 of the European Parliament and of the Council of 29 April 2004 on the hygiene of foodstuffs.

Annex II to the Regulation describes the requirements for all stages of food production, processing and distribution, related to the preparation and equipment of food premises.

The Regulation (Annex II, Chapter I, 1c) has been written:

‘(…) provides processing and storage conditions with appropriate thermal conditions sufficient to properly maintain foodstuffs at the appropriate temperature and designed in such a way that this temperature can be monitored and, if necessary, recorded.’

The ordinance does not regulate how the temperature should be monitored, how often the measurement should be done, how the data should be stored.

Temperature monitoring is also required by the quality management system including hazard analysis and critical control points (HACCP).

Pursuant to the Act of October 30, 2003 amending the Act on health conditions of food and nutrition (Journal of Laws of 2003 No. 208, item 2020) and its amendments, each production plant is required to implement and apply the principles of the HACCP system . The system consists in conducting a hazard analysis and indicating which points of the food production process are critical – there may be hazards (biological, chemical, physical) affecting the health quality of the final product. These points are designated as critical control points and should be subject to ongoing surveillance. For meat production, processing and transport, critical points are all places where the meat temperature can rise, which can lead to a rapid increase in the number of microorganisms and, consequently, damage to the meat. Most often this is associated with too high storage temperatures or breaks in the cold supply chain. When implementing the HACCP system, hazards should be defined and, taking into account their significance and likelihood of occurrence, select critical control points, determine critical conditions and determine ways to monitor each of the critical points. In this way, it is easiest to determine both the necessary number of temperature recorders in the workplace, their distribution and temperature values, the exceeding of which causes the alarm to be triggered.

How to monitor temperature in meat processing factories?

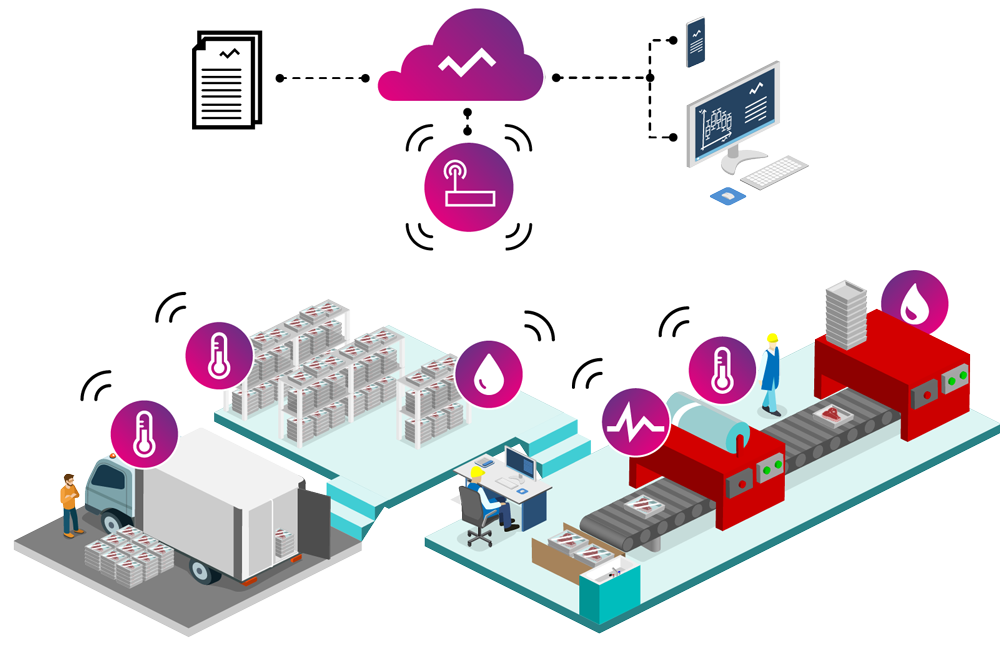

The solution designed to monitor environmental conditions in large facilities is Efento Cloud – a server platform collecting and processing data from Efento sensors. The platform is designed for objects in which from a dozen to several hundred measuring points are monitored. Data to the platform can be sent from any location, and the user can access it via a web browser.

The system consists of wireless loggers, gateways, i.e. concentrators, which receive measurements wirelessly from sensors and send them over the Internet to the cloud platform – Efento Cloud.

The server platform is the “brain” of the entire system, it is there that decisions are made to send SMS / e-mail notifications, where measurement data is collected, which the user can access from anywhere in the world. Measurement data can come from sensors located in different cities, you can freely manage them, group them according to your needs or grant access to individual sensors to selected users. The platform is maintained by Efento, so the user does not have to worry about maintenance, maintenance or software update.

Efento offers temperature sensors that allow monitoring and recording of temperature both in rooms where meat is processed and the temperature of the meat itself, thanks to a special probe, which is designed for contact with food. The loggers have a wide range of work, so they can work both in rooms where meat is processed, in cold stores and in means of transport. The sensors can work autonomously (saving measurements in the built-in memory) and in cooperation with Efento Cloud, enabling constant temperature supervision, including notifications or Efento Transport – monitoring of temperature during the transport.